This is a CALL TO ACTION

Cold-Weather Heat Pumps… But What About Dehumidification?

Predicted performance and design lessons from the OTR Green Building Electrification Project

Setting the Stage: Historic Buildings, Modern Goals

In 2024, HVAC 2 Home Performance was selected to lead the HVAC design, load analysis, and electrification feasibility study for a portfolio of affordable multifamily buildings in Cincinnati’s historic Over-the-Rhine (OTR) district.

These are nineteenth-century, double-wythe red-brick row buildings on stacked-stone foundations—constructed long before insulation, ductwork, or vapor barriers existed. Our goal was to determine how these historic buildings could be electrified cost-effectively while maintaining comfort, durability, and humidity control in a mixed, heating-dominated climate.

The study indicates a critical insight: in mixed-climate electrification, the challenge will not end with heating performance—it will begin with humidity management.

Building-Type Spotlight: Double-Wythe Brick & Stacked-Stone Foundations in OTR

| Parameter | Typical (per unit) | Notes |

|---|---|---|

| Unit Size | 800–1,000 sq ft | 2–3 rooms deep, 2 stories |

| Modeled Heating Load (pre-upgrade) | 80,000–100,000 BTU/h | ≈ 80–100 BTU/h/ft² |

| Modeled Cooling Load (pre-upgrade) | ≈ 3 tons (36,000 BTU/h) | 3–4× smaller than heating |

| Load Ratio (H:C) | 3 : 1 – 4 : 1 | Typical for uninsulated masonry |

Weatherization: The Prerequisite for Electrification

HVAC 2 Home Performance also developed the predicted weatherization scope, which will include R-49 attic insulation, R-30 floor insulation above unconditioned basements, and aggressive air sealing targeting up to an 80% blower-door leakage reduction.

Design target: reduce modeled heating loads to roughly 5 tons (60,000 BTU/h) per unit before electrification is considered feasible.

If implemented as designed, modeling predicts these envelope improvements will cut heating demand by roughly 40–60%, setting the stage for heat-pump viability. This same improvement is also expected to shrink cooling loads more dramatically, creating a new design challenge.

The Electrification Paradox

As modeled heating loads approach about 60,000 BTU/h (≈ 5 tons), the corresponding cooling loads are predicted to fall near 24,000 BTU/h (≈ 2 tons). That difference would require a system capable of serving both extremes—providing 5 tons of heating while throttling down to 2 tons or less for cooling and humidity control.

Most available cold-climate inverters cannot modulate low enough to handle both conditions. At full heating performance they meet the winter load, but during summer their minimum capacity would still be near 2 tons, effectively operating like single-stage systems for cooling. The result would be short runtimes and diminished latent removal unless controls are carefully managed.

Equipment Availability & Modulation Limits (The Reality Check)

Modeling showed that one manufacturer’s data could theoretically solve the range problem—an inverter capable of roughly 11,400–60,000 BTU/h. However, that range would only be attainable with a commercial-grade controller not supported in these residential applications.

Outside of that configuration, none of the readily available systems provided the necessary turndown. As a result, the design team selected a strategy that sizes to the cooling load (≈ 3 tons) and relies on outdoor-temperature-based lockout logic to extend heating performance before auxiliary heat engages.

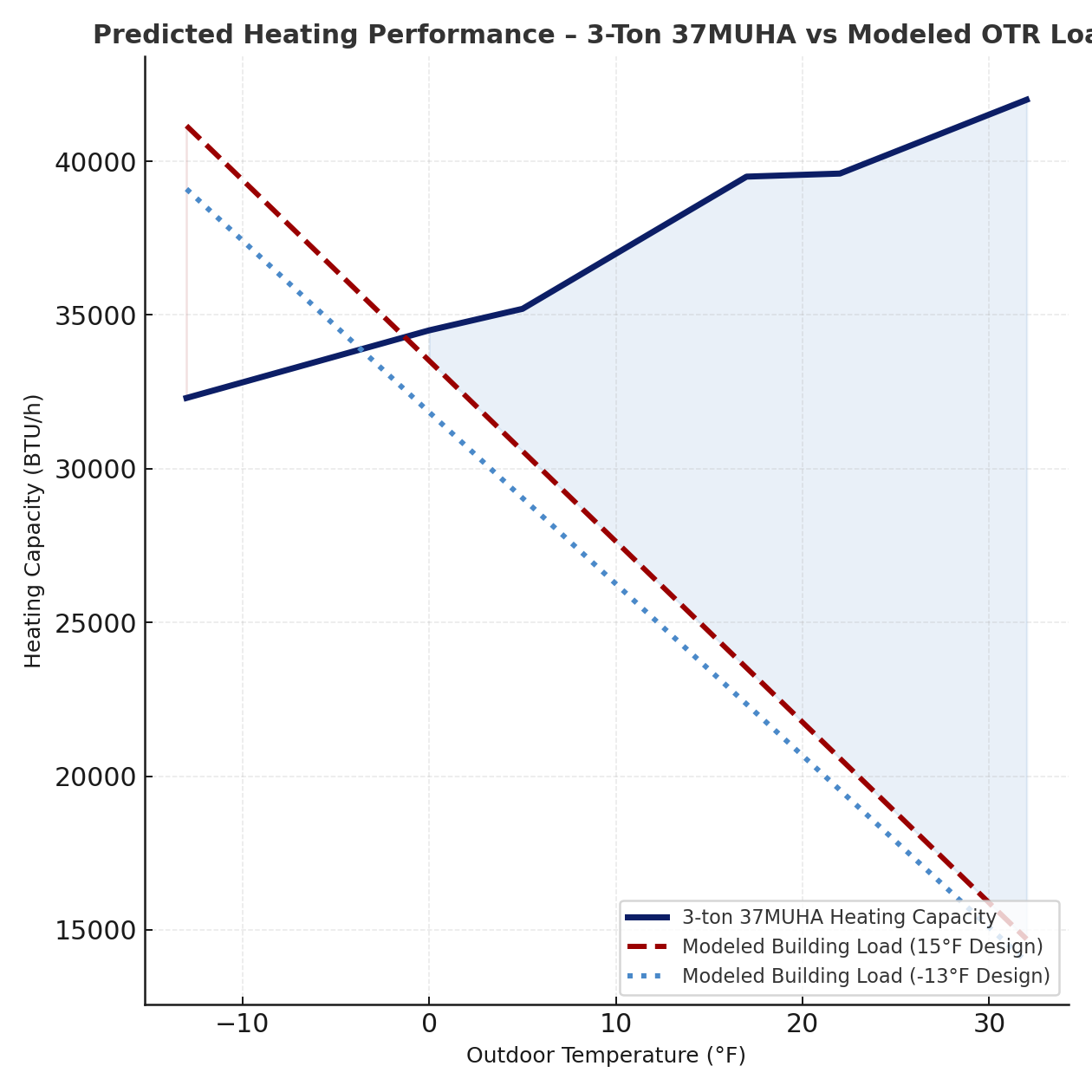

Predicted Heating Performance of the Selected 3-Ton System

Using manufacturer data for the 3-ton 37MUHA class with a compatible AH, the outdoor unit is expected to deliver approximately 42 kBTU/h at 32°F ODT, ~39–40 kBTU/h around 17–22°F, and ~32–35 kBTU/h from −13°F to 0°F (70°F indoor DB, ~1050 CFM).

AUX heat expectation: With a 15°F design target, auxiliary heat would likely be required during typical cold snaps (low-20s °F and below). With a −13°F coverage target, auxiliary heat would likely appear only in the coldest hours.

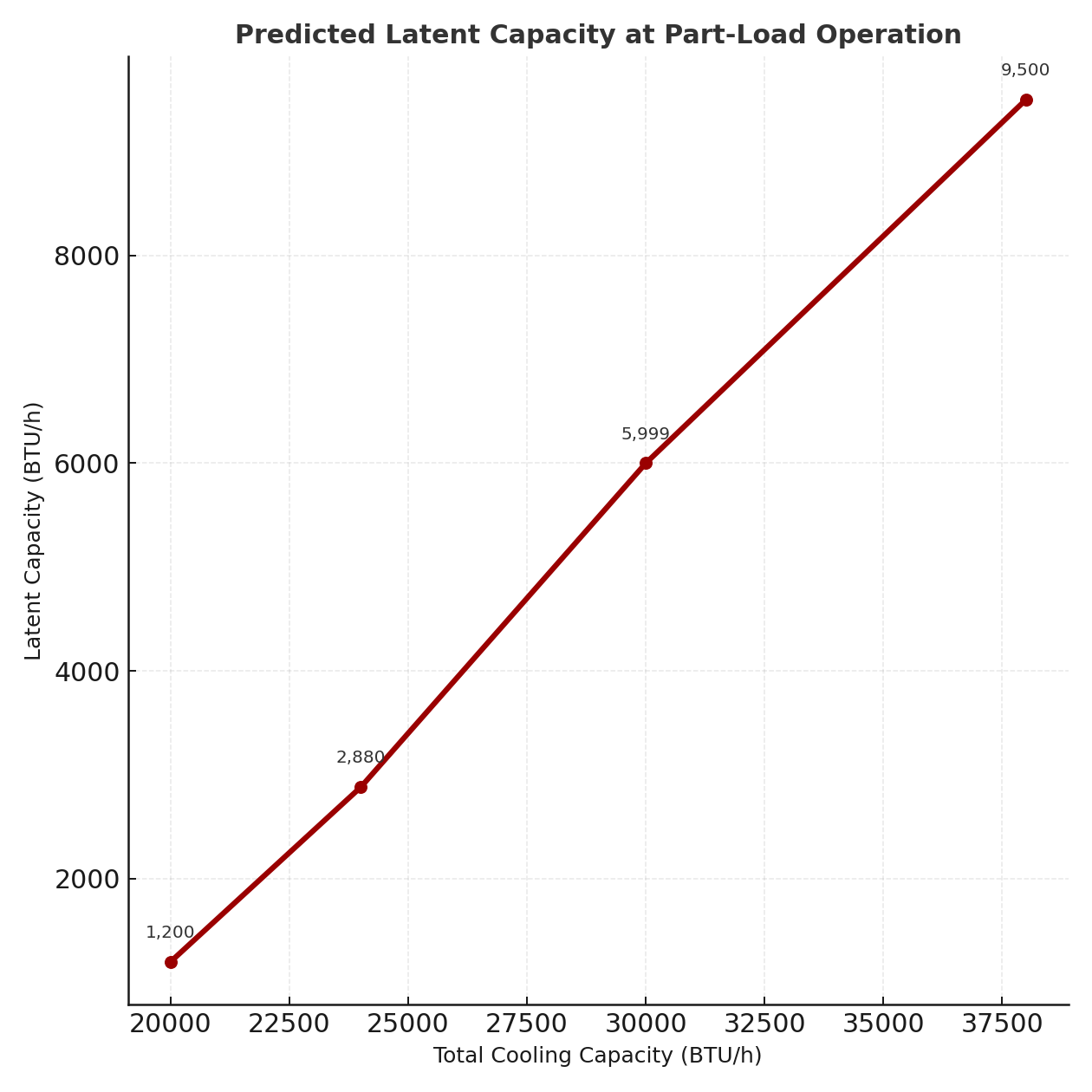

Cooling Performance & Predicted Latent at Part Load

From the same 3-ton cooling tables, the sensible-to-total (S/T) ratio is expected to climb as the inverter ramps down to match the smaller post-weatherization loads. That means latent capacity will diminish at part load. Tim De Stasio’s publicly shared field snapshot (from a different building) illustrates this behavior and aligns with our modeling.

- Near peak: total 35–40 kBTU/h, S/T ≈ 0.70–0.80 → latent ≈ 7–12 kBTU/h (about 5–9 pints/hour).

- Part load (~20–24 kBTU/h): S/T ≈ 0.83–0.95 → latent ≈ 1–4 kBTU/h (about 1–3 pints/hour).

There are no ventilating dehumidifiers in scope. Basement dehumidifiers are planned only to keep the stacked-stone foundations dry. Apartment humidity control will rely on the heat pump’s latent capacity and the control strategy described below.

Control Strategy for Commissioning

Heating Priority Below Balance

- AUX enable (W1): outdoor temperature below ~25°F and space temperature error > 15 minutes.

- Full strips (W2): OAT below ~10–15°F or time-to-setpoint > 45 minutes.

- Ventilation damper lockout: OAT below ~10°F (IAQ exceptions only).

Humidity-Biased Cooling

- If indoor RH > 55–60%, use lower fan (≈ 300–325 cfm/ton) and a colder coil target (dehum mode).

- If RH is acceptable, use normal fan (≈ 350 cfm/ton).

- Avoid the deepest turndown when RH is high; allow slightly longer runtimes to preserve latent capacity.

Predicted Unit-Level Load Reductions

All unit identifiers are redacted. Values below reflect predicted targets for weatherization-driven reduction; installations are now moving into the field.

| Unit | Size | Modeled Heating | Predicted Heating (Post-Upgrade) | Modeled Cooling | Predicted Cooling (Post-Upgrade) | Notes |

|---|---|---|---|---|---|---|

| Unit A – Historic Flat | 844 sq ft | 115,955 BTU/h | ≈ 48,800 BTU/h | 40,983 BTU/h | ≈ 24,200 BTU/h | Ground-level over stacked-stone basement; ducts brought inside. Basement dehumidifier planned for foundation moisture only. |

| Unit B – Attic Flat | ~900 sq ft | 82,511 BTU/h | ≈ 53,300 BTU/h | 51,101 BTU/h | ≈ 26,100 BTU/h | R-49 attic, R-30 floor, ~35% leakage reduction. Basement dehumidifier planned. |

| Unit C – Upper-Level Walk-Up | ~950 sq ft | 72,056 BTU/h | ≈ 63,700 BTU/h | 33,133 BTU/h | ≈ 31,200 BTU/h | R-49 attic upgrade; heating will remain near 5-ton capacity. Basement dehumidifier planned. |

| Unit D – Garden-Level Unit | ~900 sq ft | 40,447 BTU/h | ≈ 27,500 BTU/h | 22,484 BTU/h | ≈ 12,950 BTU/h | Partially below grade; > 30% predicted heating reduction. Basement dehumidifier planned. |

Economic Outlook

With A2L cold-climate heat pumps, cost modeling predicts electricity will remain roughly 20–50% more expensive than gas heating below freezing. Permanent load reduction and intelligent control will be essential for long-term economics.

Why It Matters

The OTR project demonstrates that electrification will work best, and sometimes only work when load reduction comes first; comfort will only last when humidity is controlled; and efficiency will only matter when systems fit the building.

Cold-climate heat pumps may solve most of the heating challenge. The next frontier is managing humidity and operating cost in high-mass, mixed-climate envelopes.

Closing Thought: At HVAC 2 Home Performance, we work at the intersection of HVAC, Home Performance, and Green Building. The OTR design study reinforces that these three disciplines must work together—or electrification will not deliver on its promise.

Before asking, “Can it heat?” ask, “What will the dehumidification plan be—and will the economics support it?”